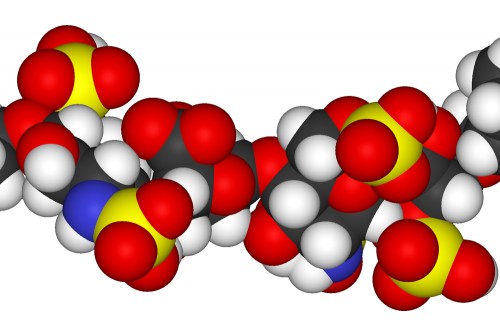

A HEPARIN MOLECULE THAT WILL BE USED as an anticoagulant in medical procedures such as dialysis and surgeries.

A HEPARIN MOLECULE THAT WILL BE USED as an anticoagulant in medical procedures such as dialysis and surgeries.The Bioengineered Heparin Project, led by Dr. Robert Linhardt, a professor here at RPI, is working to create a safe, controllable, and economically viable method of producing bioengineered heparin. Heparin is an endogenous, highly-sulfated glycosaminoglycan with the highest negative charge density of any known biological molecule, having an unclear biological function in humans. Pharmaceutically, it is used as an intravenous anticoagulant used in medical procedures, such as dialysis and surgeries, and as a coating on the inside of medical devices that contain blood, such as test tubes. Currently, the major sources of heparin are porcine intestine and bovine lung. It is difficult to control the quality of heparin obtained from these sources and this method of obtaining heparin is inefficient—only two doses can be extracted per animal. Worldwide demand is greater than 500 million doses per year. Heparin is one of the longest-used modern medicines still in widespread use, being used in the early development of modern surgery. The World Health Organization therefore lists heparin as one of the most important medicines needed to maintain a basic healthcare system, underlining the impact of success in this project having large global effects on medicine.

The Bioengineered Heparin Project was started in response to the Heparin Contamination Crisis in 2008. In 2008, there were reports of dialysis and cardiac surgery patients experiencing hyper-sensibility that caused the death of 81 people in the United States. The Food and Drug Administration determined contaminated heparin, sold by Scientific Protein Laboratories from Chinese slaughterhouses, to be the cause.

A goal of the Bioengineered Heparin Project is to create an alternative, more controllable source of heparin. The research group has been using Escherichia coli in heparin production for the bioengineering portion of their research. E. coli K5 produces N-acetyl heparosan, a precursor to heparin, that can be extracted and purified. Heparosan then undergoes a series of chemoenzymatic modification in vitro to make heparin.

This approach has been successful on a small-scale, but scaling up the production of heparin precursors is necessary for it to be produced at an industrial scale. In a collaborative project with Koffas lab, the E. coli K5 genome was sequenced and an algorithm to determine which genetic manipulations will result in the highest heparosan production ever constructed. Using E. coli K5 with genetic mutations for increased heparosan production is a viable option for producing bioengineered heparin because bacteria are inexpensive, grow quickly, and are easy to genetically engineer.

Metabolic engineering is being used to further increase anticoagulant heparin activity. Chinese hamster ovary cells were chosen for heparin production because they are capable of producing a related glycosaminoglycan, heparan sulfate. Enzymes necessary for anticoagulant heparin production were introduced to the CHO cell lines. Only a moderate increase in heparin activity was seen in these transfected cells. Enzymes essential for the biosynthesis of heparin were studied in mastocytoma cells. The results of this study helped the group bioengineer CHO cells with increased anticoagulant activity.

The project has faced a few challenges since its initiation in 2008. Its first five years were funded by the National Institute of Health. Before NIH funding was terminated, the Bioengineered Heparin Consortium, which receives funds from pharmaceutical companies, was started to help fund the project. According to Linhardt, another challenge is “getting through the valley of death.” Batches of the bioengineered heparin must be produced for clinical trials and the heparin must make it past clinical trials to be approved.

Working with a research group this large produces additional challenges. The group, now made up of about 20 people, once had roughly 40 staff members, including graduate students and undergraduate students. “A group that large is difficult to manage, supervise and fund,” Linhardt said. Although he is the most senior person in the group, Lindhardt has many experienced colleagues helping with the project. Linhardt explained, “Doctor Lingyun Li, Doctor Fuming Zhang, and Karen Coonrad are critical people in the group that help make it run. I’m just the conductor. Everyone else is good at playing the instruments. If it all works, we have a symphony.”